DHC 6510R

Powerful inverter resistance heater for annealing and controlled preheating before welding.

Price including VAT

3x 400

Power supply

[V]

25

Circuit breaker

[A]

10,8

Input

[kW]

0-60 / 180

Output voltage / current [A/V]

21

Protection

class

air

Type

of cooling

17x37x41

Dimensions

[cm]

17

Weight

[kg]

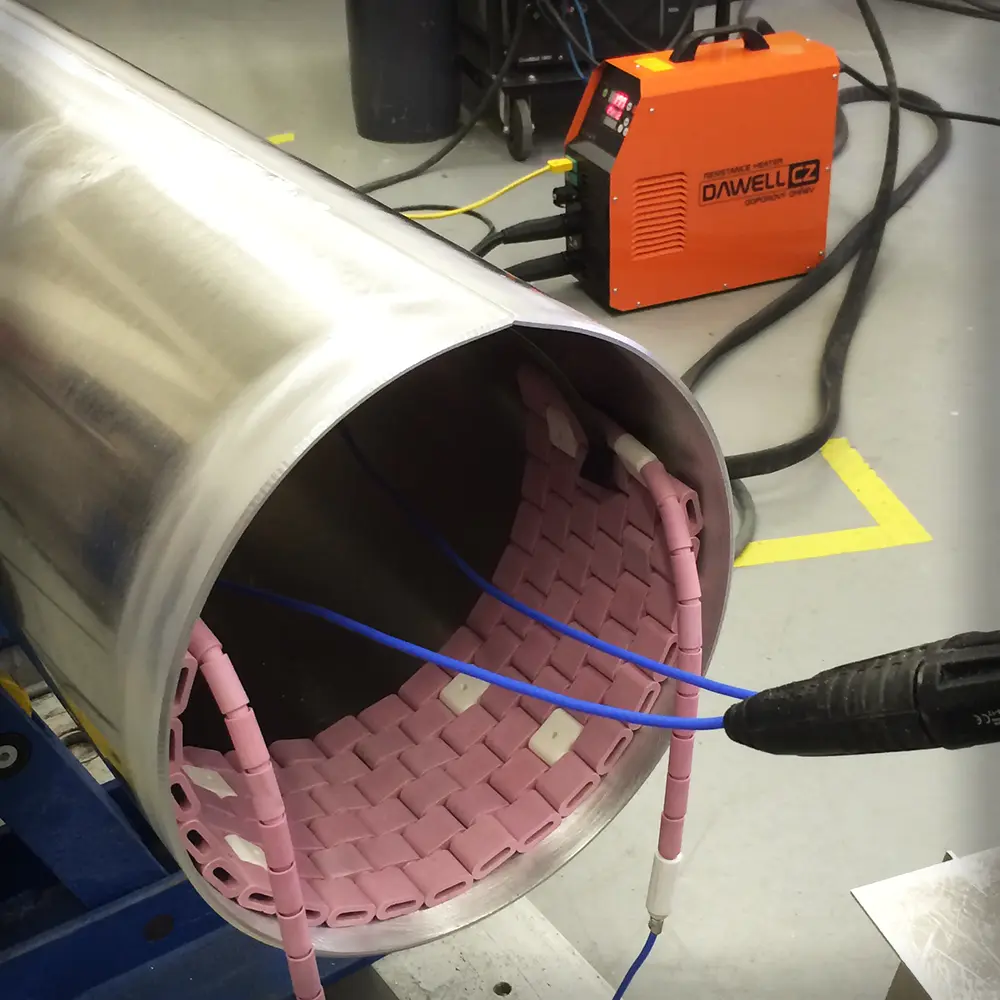

The DHC 6510R is a mobile inverter resistance heater designed primarily for controlled annealing of materials after welding to reduce stress, reduce hydrogen content and for preheating before welding up to 1050 °C.

It is equipped with a temperature and recording controller with the possibility of a higher programming level designed especially for weld annealing. It also allows multi-zone mode, linking and copying programs, setting multiple controller values and more.

The temperature can be controlled according to one of 20 user-adjustable temperature profiles/programmes with up to 180 segments or directly to a user-set temperature, which can be changed at any time as required. The heating or cooling rate, the time for which the temperature is to be maintained and the target temperature can be set independently in each profile segment and in manual temperature control mode. Of course, there is also the option of direct control of the heating output.

- Up to 4 elements can be connected

- 3 in 1 - inverter + temperature controller + logger

- Up to 1400 hours of recording, also saves error conditions

- Up to 9 machines can be connected to 1 application (up to 95 kW)

- Clear screen with parameters display

- Intuitive and easy to use

- Wide range of ceramic elements and other accessories

- Mobility and flexibility of use

- Preheating of welds of pipes, heat exchangers, steel vessels etc.

- Annealing

- Preheating of parts to precisely set temperature

- Preheating before welding and welding

- Even heating

- Industrial production, repair, renovation